Polyvinyl chloride, referred to as PVC, is a polymer of vinyl chloride monomer in peroxide, azo compounds and other initiators or under the action of light and heat polymerization by free radical polymerization reaction mechanism. Vinyl chloride homopolymer and vinyl chloride copolymer are called vinyl chloride resin.

PVC is a white powder with amorphous structure, small branching degree, glass transition temperature 77~90 ° C, 170 ° C or so began to decompose, poor stability of light and heat, above 100 ° C or after a long time of sunlight exposure, it will decompose and produce hydrogen chloride, and further automatic catalytic decomposition, causing discoloration, physical and mechanical properties are also rapidly declining, In practical applications, stabilizers must be added to improve the stability of heat and light

The molecular weight of industrial PVC is generally in the range of 50,000 ~ 110,000, with a large polydispersity, molecular weight increases with the decrease of polymerization temperature, there is no fixed melting point, 80 ~ 85 ° C begins to soften, 130 ° C becomes viscoelastic state, 160 ~ 180 ° C begins to change into viscoelastic state; It has good mechanical properties, tensile strength of about 60MPa, impact strength 5 ~ 10kJ/m2; It has excellent dielectric properties.

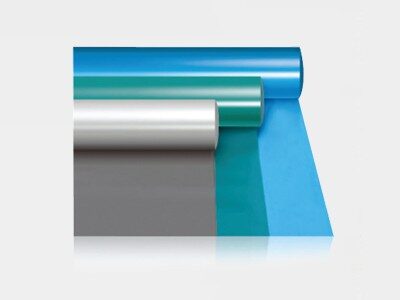

PVC was once the world’s largest production of general purpose plastic, the application is very wide. In building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipe, wire and cable, packaging film, bottles, foam materials, sealing materials, fibers and other aspects are widely used.